Product

PASSON- FEATURE

- SPEC

- MOVIE

- IMAGE

High viscosity & High share mixer

The powerhouse in continuous process homogenization

The higher the viscosity and the bigger the processing capacity,

the greater the concern regarding homogenization.

The PASSON is a simple ONE-PASS type that provides

superior dispersion quality at high viscosity with multi-level precision dispersion

and drastically lowers production time by up to 50%.

A high-shear mixer that can achieve homogenization without dead zones.

PASSON's equipmentranges from laboratory to production scales.

Request a test now and experience the breakthrough technology of MIXENMILL.

MOVIE

Examine the outstanding

performance of PASSON.

PASSON is a multi-stage impeller that minimizes dead zones during material mixing, and it is a simple ONE-PASS design that may save time and improve work efficiency.

In addition, it is an exceptional product for dissolving high-concentration polymers and for homogenizing two-liquid mixtures, such as the primary ingredients and additives.

-

MIXENMILL_PASSON RUBBER, High shear mixing for rubber

-

CMC 10% and Blue color A two-component type dispersion by PASSON

FEATURE

A HIGH-SHEARMIXER for high viscosity

manufactured using MIXENMILL's technology.

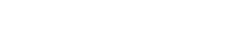

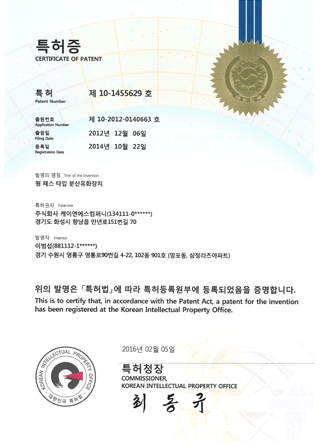

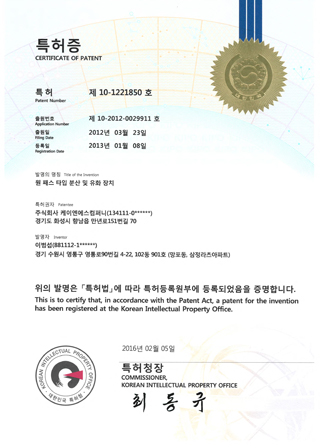

MIXENMILL's PASSON is the world's first high shear mixer for high viscosity.

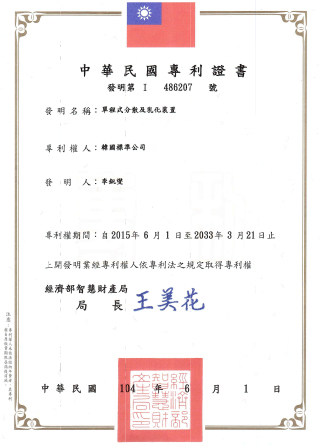

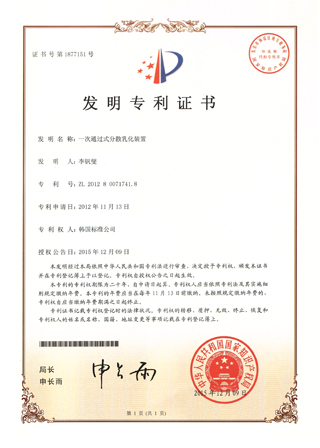

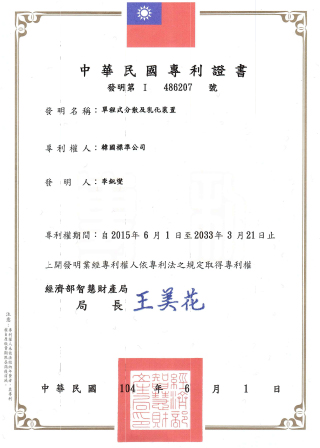

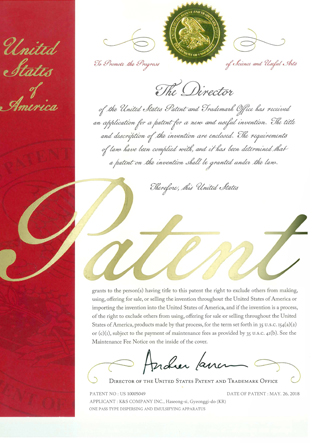

Numerous patents in Korea, China, Taiwan, Japan, and the United States attest to its technical prowess around the world.

Superb dispersion quality is provided by PASSON, which also improves process efficiency and reduces costs.

By submitting a product test application, we'll verify the dispersibility of your process.

Features of PASSON

-

01

The Ultimate of

ROTOR & STATORVertical and horizontal three-dimensional design enables fine dispersion of materials

-

02

Critical dispersion

Combining a high RPM with a uniquely designed impeller optimizes shear force.

-

03

Technology and expertise

Viscosity and dispersion may be modified to accommodate varied applications and sizes.

-

04

Cooling Jacket System

A cooling jacket system that can regulate heat production resulting from dispersion

MIXENMILL Secret - Multi-stage impeller

with 0.2mm clearance

The amazing shear force is the result of 0.2mm clearance. The consequence of the detailed dispersion is that the rotor and stator created

by KINSOL PASSON's precise 0.2mm clearance drive the raw material vertically and horizontally into the multi-layered chamber and shear at a very high speed.

PASSON's patented technology

KEY & SOLUTION

A noticeable difference,

your production can change too.

PASSON’s performance has been demonstrated through hundreds of tests starting from its development stage.

PASSON, which has already received great appreciation from several domestic and foreign companies,

demonstrates visible and actual improvements and differences, rather than mere theories and explanations.

If you need to make such modifications to your product, feel free to contact MIXENMILL.

We will deliver the KEY & SOLUTION to your process through sample testing and comprehensive consultation.

Dispersion & Cooling

The COOLING JACKET absorbs

the heat produced when the dispersing power rises.

Depending on the material being handled, some substances are temperature sensitive.

PASSON has a better cooling effect than a batch type mixer that continuously receives

heat from the tank because the material passes through the chamber without staying

in the chamber. When a temperature suitable for the characteristics of each material

is required, the required temperature can be adjusted with the COOLING JACKET

installed in the chamber.

In addition, because it is a continuous type, even though transitory dissipation heat is produced, it does not stagnate, and because it exits in the form of a pass, the dispersing force is maximized and the cooling effect is superior to that of the batch type, which absorbs stagnant heat.

Process enhancement

It minimizes time and expense

but optimizes work efficiency.

Are you creating products with a high viscosity? What method are you currently employing? Those of you who create through a series of difficult stages are aware that cutting production time reduces expenses.PASSON is the technique of emulsifying and dispersing in ONE-PASS, which drastically reduces process time and eliminates the need for manual labor throughout the process. In addition, since there is no requirement for heating to reduce viscosity or chilling for packing, expenses and labor may be reduced substantially. Therefore, it is a product that can replace the Roll-Mill, Bead Mill, or Planetary Mixer most effectively.

Various Options

SPECIAL TYPE “PASSON”

applicable to various field conditions

Several capabilities ranging from laboratory to production application! Diverse dispersion! PASSON, a high shear mixerfor high viscosity,

is scalable based on the client's procedure.

In addition to the product size, numerous material alternatives and suitable impellers are available,

allowing for the adjustment of various viscosities and degrees of dispersion.

SPECIFICATION

* production volume is the dispersion efficiency of PASSON

| MODEL | POWER | GENERAL VOLUME (Water-based) | SPEED |

| PS 002 | 2 HP | 0.5~1 L/min | 0~3,500 rpm |

| PS 005 | 5 HP | 2~10 L/min | 0~3,500 rpm |

| PS 010 | 10 HP | 5~20 L/min | 0~3,500 rpm |

| PS 020 | 20 HP | 10~30 L/min | 0~3,500 rpm |

| PS 030 | 30 HP | 20~70 L/min | 0~3,500 rpm |

| PS 050 | 50 HP | 30~100 L/min | 0~1,750 rpm |

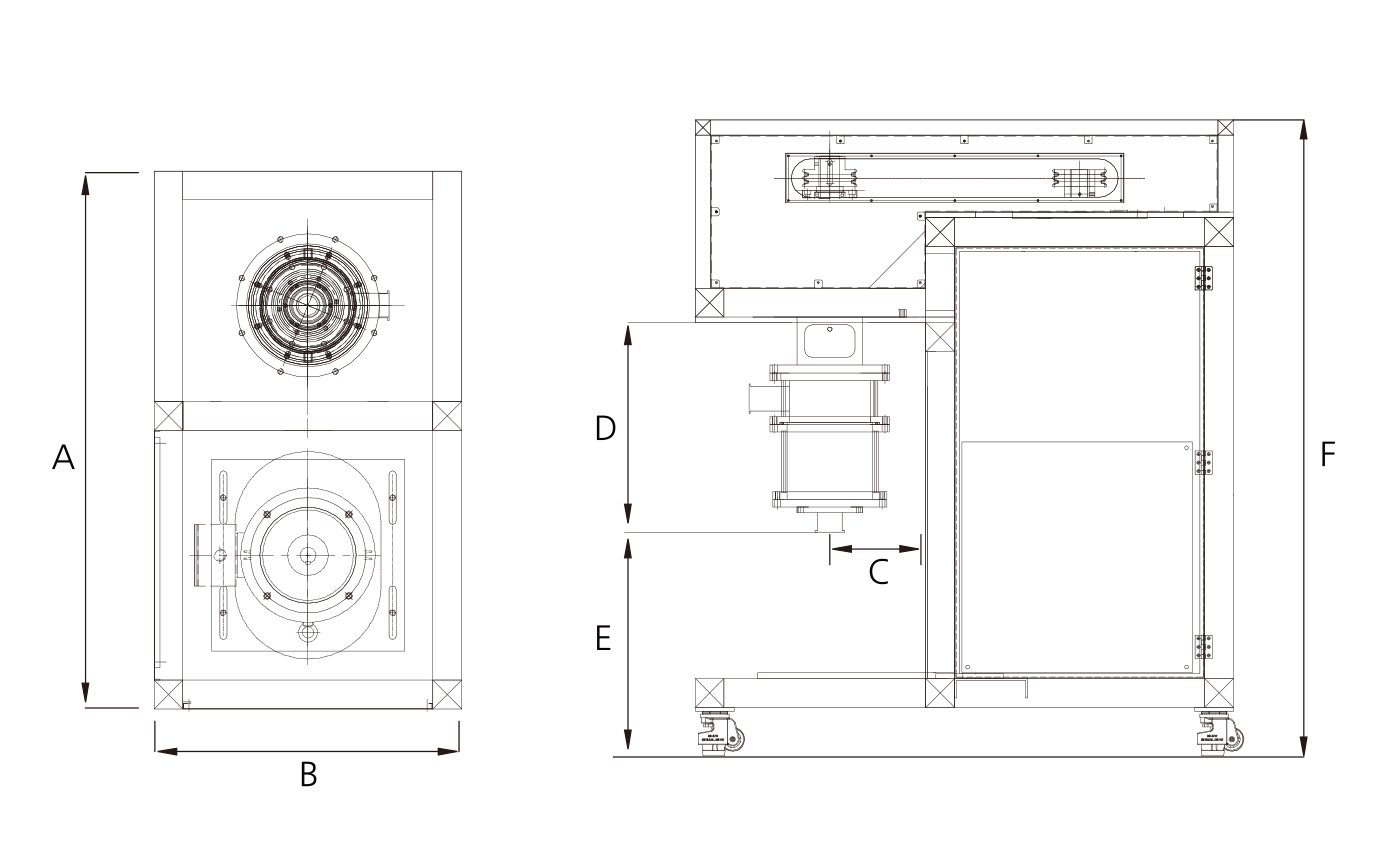

SIZE (Unit : mm)

* Configuration options may change specifications. Please inquire us separately for higher models.

| MODEL | A | B | C | D | E | F |

| PS 002 | 525 | 405 | 118 | 319 | 245 | 1165 |

| PS 005 | 1300 | 730 | 220 | 330 | 540 | 1320 |

| PS 010 | 1350 | 765 | 235 | 4335 | 562 | 1425 |

| PS 020 | 1400 | 800 | 250 | 544 | 583 | 1528 |

| PS 030 | 1780 | 1000 | 385 | 650 | 640 | 2175 |

| PS 050 | 2160 | 1180 | 520 | 784 | 697 | 2824 |

Excellent Technology

We are confident in displaying

the outstanding performance of PASSON!

Anyone can assert that their products are superior. However, we will show you. See for yourself the multiple product development tests and test results

from numerous companies. If you experience the visual dispersion effect of PASSON, you will understand why the world's attention is on PASSON.

MORE VIDEOS

-

PASSON RUBBER (Rubber dispersion, High shear mixing for rubber)

-

CMC Dispersion by PASSON

-

CMC 10% and Blue color Two-component type dispersion by PASSON

Service is being prepared

We are preparing to provide higher quality services to our customers.

We plan to page open soon.