Product

TANDEM MIXER- FEATURE

- SPEC

- MOVIE

- IMAGE

Double Core Features

It perfectly disperses even light powder with strong flow

in both the top-to-bottom and bottom-to-top directions.

The dual rotor and stator provide a strong flow to the top and bottom of the container, as well as powerfully sucking, emulsifying, and dispersing powder and oil with a low specific gravity floating on the surface of the liquid.Therefore, the outcome of emulsification and dispersion of ideal powder may be checked in a shorter amount of time.

MOVIE

Examine the outstanding

performance of TANDEM MIXER

TANDEM MIXER has a similar driving principle to HOMO MIXER, but its structure has been updated for particular applications. By moving up and down, powerful whirlpools are generated, and the raw materials are sucked up and down, dispersed vigorously, and finally ejected to the side. It is useful for emulsifying and dispersing powders and oils with a low specific gravity that floats on the surface of a liquid.

-

MIXENMILL_CARBOPOL 4% + WATER, TANDEM MIXER test

-

MIXENMILL Tandem mixer (KOR_200317)

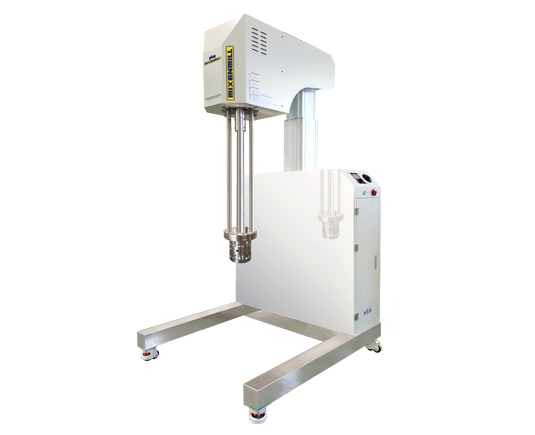

Vortex in Both Directions

With its unique dual-structure impeller,

it disperses substances more quickly and precisely.

In TANDEM MIXER, one more rotor is added to the existing HOMO MIXER, and a specially designed stator that maximizes the dispersion force is applied to form vortices in both directions, up and down.This whirlpool collects and disperses light-specific-gravity raw materials such as powder and oil floating on the liquid surface into the impeller, allowing superior results to be attained without additional equipment.Moreover, even when dispersing powder in a liquid phase with high viscosity or when the viscosity is rapidly increasing during dispersion, the injected raw material is absorbed into the impeller without a gap to float on the surface due to the whirlpool generated at the top, and bottom, allowing dispersion at room temperature.

Fast & Efficient Technology

Thickener powder that immediately

floats and clumps on the liquid's surface!

Now you can dissolve and

scatter more quickly and effectively!

In the process of dissolving powdered thickeners such as CARBOPOL, CMC, and GUM, a DISSOLVER-type mixer is frequently employed.However, as seen in the belowvideo, when the thickening powder is applied to the liquid phase, it frequently coagulates and floats and does not dissolve efficiently. In order to remedy this issue, extra procedures such as heating are implemented; however, in most situations, the outcomes are of low quality in relation to the amount of time and cost required.

With the powerful whirlpool formed by the double-structured impeller, the TANDEM MIXER allows the light-specific-gravity thickening powder to be pumped directly into the impeller, dispersing, and dissolving it in an instant. Therefore, superior melting results may be evaluated more rapidly and affordably than using a DISSOLVER or standard HOMO MIXER.

RECOMMENDATION

Procedure for effective

use of TANDEM MIXER

Clients who want rapid dispersion of powder with low specific gravity in liquid!

Clients who want rapid dispersion of powder with low specific gravity in liquid!

Clients who want to emulsify and spread oil materials more quickly and efficiently!

Clients who want to emulsify and spread oil materials more quickly and efficiently!

Clients who want to dissolve thickeners such as CMC, Carbopol, and Gum in liquid ingredients!

Clients who want to dissolve thickeners such as CMC, Carbopol, and Gum in liquid ingredients!

Clients who wish to inject powder into high-viscosity liquid substances, such as resin, to disperse them!

Clients who wish to inject powder into high-viscosity liquid substances, such as resin, to disperse them!

Clients who wish to disperse viscous raw materials at room temperature rapidly and effectively!

Clients who wish to disperse viscous raw materials at room temperature rapidly and effectively!

Clients who are dissatisfied with the existing process's dispersion and emulsification outcomes and wish to improve!

Clients who are dissatisfied with the existing process's dispersion and emulsification outcomes and wish to improve!

Clients who wish to enhance process time and product quality effectively!

Clients who wish to enhance process time and product quality effectively!

Clients who are searching for reasonably priced, high-quality equipment to replace pricey international products!

Clients who are searching for reasonably priced, high-quality equipment to replace pricey international products!

2 Type Products

Depending on the procedure,

you have two equipment options.

-

Standard type

It is an open-type equipment comparable to the existing HOMO MIXER, and the whirlpool is formed in both directions at the top and bottom. As a consequence, it is a model with outstanding process efficiency because it can achieve a higher quality dispersion result in less time than the existing HOMO MIXER. It has a basic design and is simple to maintain, making it easy to clean precisely, which is why so many clients use it.

-

Vacuum, Pressure type

This type is tailored for procedures that demand a vacuum condition or materials that are pressure-sensitive. By attaching the mixing component to the tank and applying the LIP-SEAL, it may be driven in both vacuum and pressure conditions. This shape applies to vacuum/pressure type models in particular, and it is more cost-effective since it can be created by putting only the MIXING PART in the existing general-type tank.

Various Options

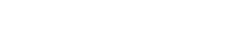

All capabilities, from small laboratory usage to very large production use, are accessible.

Most companies either deal with laboratory usage or have only dealt with manufacturing use. It becomes frustrating when, either scaling up or scaling down, the performance or design imagined during the test phase is not fulfilled owing to a lack of expertise and knowledge. As an expert in high shear mixers, MIXENMILL manufactures a comprehensive selection of laboratory and industrial scales. We supply necessary solutions so that successful laboratory samples may be scaled up for production without difficulty.

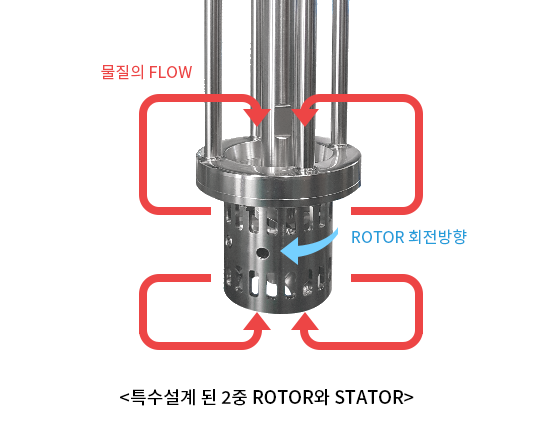

SPECIFICATION

| MODEL | POWER | GENERAL VOLUME (Water-based) |

IMMERSION DEPTH (max/min) |

SPEED | ELECTRICAL DATA |

| TM 1HF | 0.5HP | 5L | 260mm / 70mm | 0~6,000 rpm | SINGLE-PHASE 220V |

| TM 001 | 1HP | 10L | 350mm / 100mm | 0~5,100 rpm | |

| TM 003 | 3HP | 30L | 630mm / 160mm | 0~3,500 rpm | 3-PHASE 220/380/440V Choice |

| TM 005 | 5HP | 80L | 760mm / 170mm | 0~3,500 rpm | |

| TM 010 | 10HP | 150L | 900mm / 180mm | 0~3,500 rpm |

* IMMERSION DEPTH is the maximum and minimum shaft depth that can be immersed in the sample.

*GENERAL VOLUME is the water-based capacity of each model that is typically employed.

* Please inquire us separately for high-end models.

SIZE (Unit : mm)

* Specifications may vary based on configuration options; for adjustments to lift options, please contact us separately.

| MODEL | A | B | C | D | E | F | G | |

| PILOT SCALE | TM 1HF | 400 | 380 | 300 | 150 | 350.5 | 313.5 | 880 |

| TM 001 | 600 | 560 | 420 | 229.5 | 424.5 | 625 | 1300 | |

| INDUSTRIAL SCALE | TM 003 | 600 | 560 | 420 | 311 | 503 | 544 | 1613 |

| TM 005 | 1000 | 950 | 800 | 333 | 797 | 907 | 2139 | |

| TM 010 | 1330 | 1050 | 870 | 335 | 990 | 1111 | 2594 | |

Excellent Technology

We demonstrate with assurance

the superior performance of TANDEM MIXER

Anyone can assert that their products are superior. However, we will show you. See for yourself the multiple product development tests and test results from numerous companies.

MORE VIDEOS

-

Oligosaccharide + thickener 5.2% dissolved BY TANDEM MIXER

-

Carbopol 4% Dispersion by TANDEM MIXER

-

Soybean Protein Isolate (ISP) Test

-

Dispersion of HPMC using TANDEM MIXER

-

Melting of Guar gum - Resolve quickly at room temperature with TANDEM MIXER

-

Cocoa Powder MIXING by TANDEM MIXER

Service is being prepared

We are preparing to provide higher quality services to our customers.

We plan to page open soon.