2000

PARTNERS0

YEARSwe have developed alongside

3,400 domestic companies

A company's capability is not determined by annual history.

The primary factor is the amount of client contact.

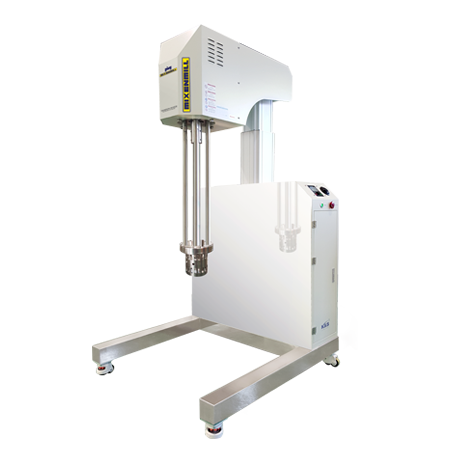

MIXENMILL competes with European nano emulsification and dispersion system manufacturers with a 150-year history in the undeveloped nanoemulsion and dispersion system market.

Even though the company's commercial history spans only 17 years, it has contributed to the growth of domestic enterprises by resolving issues with around 3,400 companies.

A company's capability is not determined by annual history.

The primary factor is the amount of client contact.

MIXENMILL competes with European nano emulsification and dispersion system manufacturers with a 150-year history in the undeveloped nanoemulsion and dispersion system market.

Even though the company's commercial history spans only 17 years,

it has contributed to the growth of domestic enterprises by resolving issues with around 3,400 companies.

Secondary Cell

It is feasible to produce a high-quality solution that stably emulsifies and disperses the negative and

positive electrodes of the secondary battery solution, which will be the foundation of the future energy industry.

Electronic Material

It is the even distribution of raw materials that defines the quality of products in the field of electrical materials.

The products of MIXENMILL are ideal for dispersing viscous material.

Chemical

In a chemical industrial process, the quality is determined by the particle size distribution.

Recognized for their technological brilliance, MIXENMILL's products are utilized in numerous areas.

Cosmetic

In the production of cosmetics, an evenly mixed product with a high-performance emulsifier

and dispersant can prevent layer separation during dispersion and increase product quality.

BIO·PHARMA

It is recognized as the most effective equipment for dispersing coating liquids such as TiO2, pigments, and eye drops,

and it can manufacture high-viscosity ointment products of exceptional quality while saving production time and expenses.

Food

It is suitable for food-specific stable emulsification, dissolving, and mixing.

Numerous companies place a premium on HACCP- and GMP-compliant products.

Begin with MIXENMILL on

process enhancement and energy saving.

Beginning with PASSON, a high-viscosity, high-shear mixer, we introduced MIXENMILL, which can operate concurrently

with nano-mixing and nano-milling functions, for the first time in the world, resulting in standing shoulder to shoulder with the foreign leading enterprises.