Product

INLINE MIXER- FEATURE

- SPEC

- MOVIE

- IMAGE

Strong Pumping & High share mixer

The continuous circulation structure produces unparalleled dispersion outcomes!

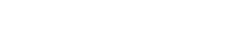

The INLINE MIXER from MIXENMILL features a structure in which PUMPING and HIGH SHEAR simultaneously occur. Compared to HOMO MIXER 2 to 5 additional stators are installeddepending on the model, to enable greater emulsification and dispersion.In addition, the sanitary design (CIP) that can be cleaned in a single location, as well as several other alternatives and structures, broaden the available options.

MOVIE

Examine the outstanding

performance of INLINE MIXER

INLINE MIXER employs the "pump and circulation" principle and utilizes multi-stage rotors and stators to improve dispersion performance. With a horizontal structure, the ROTOR and STAORT are at least 2 layers (STAGE), so the dispersion and emulsification efficiency is excellent, and it has more excellent performance when dispersing and emulsifying substances with a heavy specific gravity. In addition, since it has its own pumping function, the result can be easily transferred to the next process without a separate transfer device.

-

INLINE MIXER Egg and sugar mixing (emulsified, dispersed)

-

INLINE mixer Introduction video of MIXENMILL(KOR 200317)

KEY & SOLUTION

Pumpable high shear mixer for medium and low viscosity

Due to its resemblance to a pump, people who have never seen an in-line mixer refer to it as an in-line pump. However, mixing, which includes dispersing and emulsifying, is an essential function of an inline mixer, and dispersing power technology is incorporated.

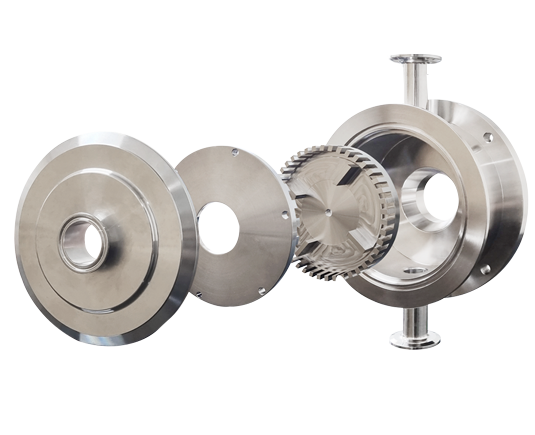

It may be described as a high shear mixer in which a fine rotor and stator perform multi-stage dispersion during the discharge of forcefully suctioned materials. In low- and medium-viscosity fluids, it is most efficient to circulate only the in-line mixer if a pump is added to enhance the flow rate; otherwise, the dispersion performance is significantly degraded.

World's best technology

Application of super-fine rotor & stator clearance with outstanding dispersion effect

MIXENMILL applied 0.2mm clearance between rotor and stator to enhance dispersion effect, which is the highest level in Korea and the world.To close the clearance, more precisetechnology is essential since the rotating shaft must not shake at high speeds, and MIXENMILL creates world-class products using this technology. Numerous businesses have already encountered and experienced our enhanced dispersion quality.

Excellent Dispersion & Emulsification

It produces excellent dispersion efficiency with multi-stages.

INLINE MIXER is also a high shear mixer with the same principle as HOMO MIXER and is a product that disperses and emulsifies samples using shear force between the rotor and stator.In-line mixers feature a horizontal structure and may install rotors and stators in numerous stages, unlike vertical HOMO MIXERS. The smallest model has 2 stages, while the largest model has 5 stages. In addition, Rotor & Stator's dispersion and emulsification efficiency are superior to that of a single-stage HOMO MIXER for samples that pass through it via pumping and circulation.

* However, HOMO MIXER may be suitable depending on the installation environment or procedure; please ask the sales staff prior to making a purchase.

Advantages

In what circumstances is it preferable

to utilize an INLINE MIXER?

INLINE MIXER can produce the greatest efficiency in the viscosity range of 1~5,000cps. (However, it may vary depending on the head and sample.) For small capacity, a hopper is installed and used, but when the processing capacity increases, it is also used by connecting to a tank. (If you have an existing tank, you can also connect it to the existing tank.) Both INLINE MIXER and HOMOMIXER have the same basic functions of emulsification and dispersion, but as the throughput increases, INLINE MIXER is more efficient, so INLINE MIXER is widely applied to ultra-large reactors.

-

INLINE MIXER

It is a type of agitation that utilizes pumping and circulation. As the size rises, so does the number of rotors and stators, making it more sophisticated than HOMO MIXER. When the low-specific-gravity powder is introduced, however, it remains suspended in the hopper, which is a disadvantage compared to homo mixers.

-

HOMO MIXER

It may be utilized with ease for BATCH operations involving one tank or one barrel. It consists of a pair of rotor and stator,and the principle of sucking in and dispersing the raw material is useful for powder input or liquid phase pre-mixing.

Various Options

Consult with MIXENMILL, the

"INLINE MIXER specialist."

Have you ever been harmed by the negligent service and inferior equipment of an amateurish machine manufacturer? Now, if you engage with K&S Company, you may quickly and easily obtain advice on the appropriate equipment through swift consultation.Based on our extensive knowledge of dispersion process technology, we offer professional guidance to clients who desire better equipment, increased productivity, and quality enhancement. In addition, you may enjoy A/S on a different level with responsiveness and speedy service that differ from foreign equipment providers. In addition, a test program awaits you to determine whether equipment and techniques are appropriate for your product.

SPECIFICATION

| MODEL | POWER | SPEED | STAGE | INLET/OUTLET | GENERAL VOLUME (Water Standards) |

| IM 001 | 1 HP | 0~4,800 rpm | 2 | 1S / 3/4S | 2L |

| IM 002 | 2 HP | 0~3,500 rpm | 2 | 1.5S / 1S | 50L |

| IM 005 | 5 HP | 0~3,500 rpm | 2 | 2S / 1.5S | 500L |

| IM 010 | 10 HP | 0~3,500 rpm | 3 | 2.5S / 2S | 1,000L |

| IM 020 | 20 HP | 0~3,500 rpm | 3 | 3S / 2.5S | 2,000L |

| IM 030 | 30 HP | 0~1,750 rpm | 3 | 4S / 3S | 3,000L |

| IM 050 | 50 HP | 0~1,750 rpm | 3 | 5S / 4S | 5,000L |

* 'STAGE' is each number of ROTOR & STAGE.

* The diameter of the inlet/outlet S is a Sanitary Inch.

* The processing capacity is the maximum water-based capacity of the batch process when the hopper or tank is connected, and it is a separate concept from the flow rate.

* Please inquire us separately for high-end models.

* Depending on the material or process, SPEED can be changed beyond the standard specification.

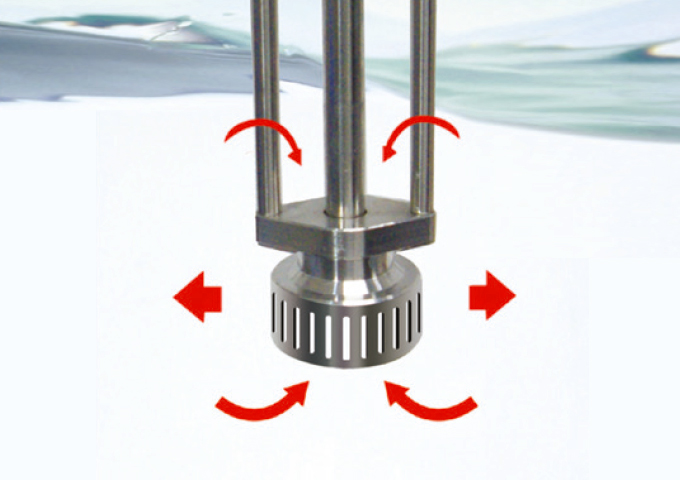

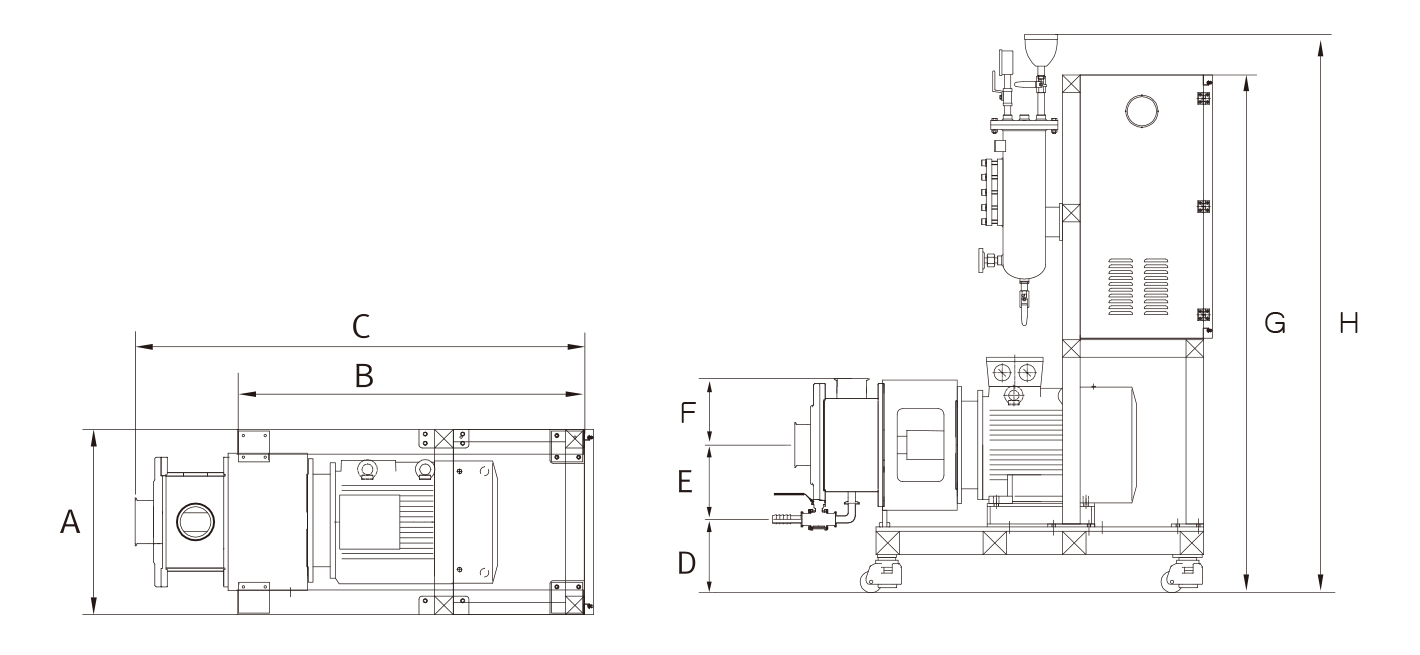

SIZE - MIXING PART (Unit : mm)

* Configuration options may change specifications. Please inquire us separately for higher models.

| MODEL | A | B | C | D |

| IM 001 | 465.5 | 131.7 | 90.2 | 69 |

| IM 002 | 524.5 | 192.5 | 136 | 82.5 |

| IM 005 | 622 | 207 | 150.5 | 92 |

| IM 010 | 713.5 | 148 | 178 | 111.5 |

| IM 020 | 923.7 | 206.5 | 188 | 158 |

| IM 030 | 1046.5 | 237.5 | 201 | 165 |

| IM 050 | 1152.5 | 246.5 | 289.5 | 168 |

SIZE - INLINE MIXER (Unit : mm)

* Configuration options may change specifications. Please inquire us separately for higher models.

| MODEL | A | B | C | D | E | F | G | H |

| IM 001 | 340 | 490 | 507.5 | 162.8 | 131.7 | 90.2 | 1362 | 1362 |

| IM 002 | 380 | 413 | 537.5 | 102.5 | 192.5 | 136 | 1074.5 | 1320 |

| IM 005 | 480 | 610 | 681 | 154.5 | 207 | 150.5 | 1300 | 1516 |

| IM 010 | 480 | 610 | 724.8 | 177 | 204.5 | 178 | 1300 | 1516 |

| IM 020 | 600 | 760 | 945 | 205 | 206.5 | 188 | 1515.5 | 1515.5 |

| IM 030 | 600 | 760 | 1000 | 194 | 237.5 | 201 | 1515.5 | 1515.5 |

| IM 050 | 730 | 887 | 1155 | 281.5 | 246.5 | 289.5 | 1697.5 | 1697.5 |

Excellent Technology

We demonstrate with assurance

the superior performance of INLINE MIXER!

Check the performance and impact of INLINE MIXER, which has been tested and proven by several enterprises and research institutions, from experimentation to production! You will be impressed not only by the emulsification and dispersion effect but also by the equipment's silent and vibration-free operation, despite its enormous size.

MORE VIDEOS

-

Improving the mixing process of jelly production

-

Silicon binder and graphite in INLINE MIXER

-

EGG & SUGAR DISPERSION by INLINEMIXER

-

Crushing tangerine peel by INLINE MIXER

-

Garlic & Ginger Crushing in INLINE MIXER

-

Crushed boiled beans in INLINE MIXER

-

Grinding Soaked Rice in INLINE MIXER

-

Silicone oil emulsification (for laboratory use) in INLINE MIXER

-

Bunker C oil and coke dispersion in INLINE MIXER

Service is being prepared

We are preparing to provide higher quality services to our customers.

We plan to page open soon.