Product

POLIMIX- FEATURE

- SPEC

- MOVIE

- IMAGE

Powder & Liquid Mixer

high-efficiency powder suction

high shear mixer that takes

the working environment and

safety into account

In most manufacturing plants, injecting and dispersing powder into a solution is a simple but critical procedure. However, pouring and dispersing powder with a very low specific gravity into the liquid phase is a time-consuming and inefficient procedure.POLIMIX, MIXENMILL's innovative concept equipment, works by sucking powder and dispersing it straight into the liquid phase, eliminating the scattering of powder with a low specific gravity during the dispersion process. As a result, it is an eco-friendly, high-performance piece of equipment that not only provides outstanding dispersion but also prevents workplace pollution, improves worker health, and decreases the risk of dust explosion.

MOVIE

Check out the performance of POLIMIX.

POLIMIX is an exceptional technological product that can suction and disperse

at the same time, and the usage of MIXENMILL's POLIMIX may reduce the dispersion process.

-

When manufacturing drugs with POLIMIX of MIXENMILL, inhalation and dispersion of xanthan gum

-

Polimix Introduction video of MIXENMILL (KOR_200317)

FEATURE

Research and production

environments determine competitiveness.

As newly built pharmaceutical facilities satisfy the European standard of EUGMP as well as Korea Good Manufacturing Practice(KGMP) the demand

for manufacturing sanitation environment is rising significantly. Not just pharmaceuticals, but also foods, chemicals, electronic materials,

and cosmetics. It is especially difficult to clean and handle if colored powder, such as carbon black, is blown and the floor becomes polluted.

Features of POLIMIX

Because there is no particle scattering, POLIMIX allows you to maintain a clean experiment and manufacturing environment, which will quickly become an unseen

competitive advantage. Moreover, because the powder is not poured from the top of the container, it does not clump on the container wall or the top of the agitation axis, making the container quite easy to clean.

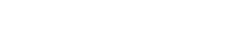

Suction & Dispersion

Powder suction and dispersion, two processes running concurrently!!

Fill the container with a solution before starting Polimix, and the specially designedflow impeller circulates the solution. The solution's high flow produces an aspiration action and a vacuum suction force.When the valve is opened and the powder is drawn in, the powder collides with the solution in front of the rotor/stator and the two dispersed simultaneously.

Polimix is much more than a powder inhaler. It is a high-quality powder suction and dispersion device that incorporates years of MIXENMILL's inline mixer technology.

Process enhancement

The powder dispersion process is significantly shortened.

Some powders have the property of aggregation when put into a solution. These powders require high dispersing power and time to re-disperse the once agglomerated powder particles. POLIMIX, a new MIXENMILL product, sucks up the powder with the same sucking power as a vacuum cleaner and as soon as the inhaled powder comes into contact with the solution (before it agglomerates), it is vigorously dispersed via the rotor/stator, considerably lowering total powder dispersing time and enhancing dispersing efficiency.(Depending on the process, it may be lowered to 1/10, representing a tenfold increase in process efficiency.)

Various Options

Innovative powder high shear mixer!

Consulting on production and procedure is also available.

you ever been harmed by the negligent service and inferior equipment of an amateuricalmachine manufacturer? Now, if you engage,

you may quickly

and easily obtain advice on the appropriate equipment through swift consultation. Based on our extensive knowledge of dispersion process

technology, we offer professional guidance to clients who desire better equipment, increased productivity, and quality enhancement. In addition, you may enjoy

A/S on a different level with responsiveness and speedy service that differ from foreign equipment providers. In addition, a test program awaits you to determine whether equipment and techniques are appropriate for your product.

SPECIFICATION

| MODEL | POWER | GENERAL VOLUME (Water-based) |

SPEED | POWDER INCORPORATION |

| PM 010 | 10 HP | 500L | 0~3,500 rpm (rpm Changeable) |

100~200(kg/h) |

| PM 020 | 20 HP | 1,000L | 0~3,500 rpm (rpm Changeable) |

200~300(kg/h) |

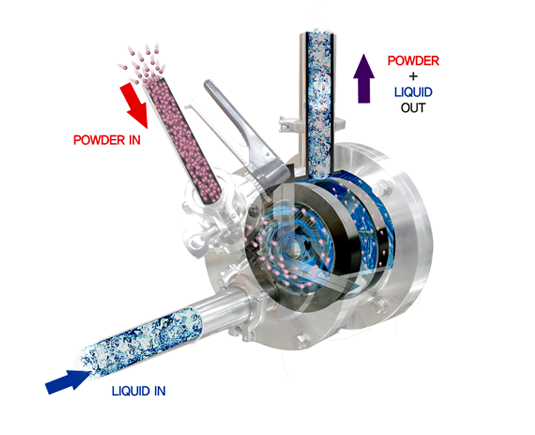

SIZE (Unit : mm)

* Configuration options may change specifications. Please inquire us separately for PM 020.

| MODEL | A | B | C | D | E | F | G | H | I |

| PM 010 | 480 | 705.3 | 179.5 | 164 | 76 | 532 | 106 | 1300 | 1516 |

Excellent Technology

Examine the remarkable performance of POLIMIX,

which provides multiple advantages with only one product

Experience the performance of POLIMIX with new and various functions such as work environment

enhancement,worker safety, superior dispersion quality, and process time savings via video.

MORE VIDEOS

-

Pectin Dispersion by POLIMIX

-

Xanthan gum Dispersion by POLIMIX

-

Fumed silica Suction & Dispersion by POLIMIX

Service is being prepared

We are preparing to provide higher quality services to our customers.

We plan to page open soon.